Nigeria’s Broiler Feed Production: Opportunities, Challenges & Smart Equipment Solutions

With a population of over 220 million and a fast-growing poultry industry, Nigeria is becoming one of Africa’s most promising markets for broiler feed production. However, traditional production methods and rising compliance requirements are creating new challenges for farmers and feed producers.

This guide breaks down the market opportunities, key pain points, and how professional feed machinery can help Nigerian producers cut costs, improve quality, and boost efficiency.

1. Introduction: Why Nigeria Is a Hot Market for Broiler Feed — and Why It’s Still Hard to Produce

1.1 A booming poultry industry driving massive feed demand

Nigeria’s urbanization and rising chicken consumption (8–10% YoY growth) are pushing poultry farming to scale up rapidly. Farmers are shifting from backyard systems to cooperatives and fully commercial farms — creating huge feed demand.

Key fact: Nigeria has an annual broiler feed deficit of over 3 million tons. Local production covers only 60%; the rest depends on imports.

This opens a major opportunity for local producers and machinery suppliers.

1.2 The four biggest challenges of traditional feed production

Despite the market potential, most Nigerian producers still rely on manual or semi-mechanized processes, facing four main problems:

- Low efficiency – Manual mixing and crushing limit output to less than 3 tons/day.

- Unstable feed quality – Human error causes 5%+ mixing inaccuracies, affecting growth and meat quality.

- High waste & high cost – Poor pre-processing causes low raw-material utilization (≈85%) and higher electricity use.

- Compliance issues – Meeting NAFDAC standards is difficult without proper hygiene control, testing, or data records.

1.3 Why professional feed machinery is the key

Using the right machinery designed for Nigerian raw materials and local standards is the most effective way to solve these issues.

This article will walk you through market needs, equipment selection, Nigerian customer cases, and full solutions to scale your feed production profitably.

2. What Nigerian Broiler Feed Producers Really Need: Market, Raw Materials & Compliance

2.1 Different farm sizes have different needs

Nigeria’s broiler feed demand can be divided into three levels:

Small farms (500–2,000 birds) – 1–5 tons/day

- Focus on low cost and easy operation

- Prefer compact machines for self-use feed production

Medium cooperatives (2,000–10,000 birds) – 5–20 tons/day

- Need higher output and more stable quality

- Want flexibility to produce multiple feed types

Large commercial farms & feed mills – 20+ tons/day

- Require automation, data monitoring, and NAFDAC compliance

- Aim for stable, large-scale feed distribution

2.2 Nigerian raw materials require special processing

Local broiler feed formulas usually include:

- Maize (40–50%) – high moisture 15–18%; needs proper drying/screening

- Soybean meal (20–25%) – hard texture; needs precision hammer-mill crushing

- Fish meal (5–10%) – absorbs moisture easily; needs anti-caking mixing and corrosion-resistant parts

2.3 NAFDAC compliance requirements

NAFDAC regulates feed quality with strict standards:

- Heavy metals: Pb, Hg ≤ 0.1 mg/kg

- No salmonella allowed

- Nutritional targets:

- Starter feed protein ≥ 20%

- Broiler finisher energy ≥ 3000 kcal/kg

- Full production records + monitoring

Machines must therefore ensure hygiene, accuracy, and automatic data logging.

3. How Professional Equipment Solves Nigeria’s Biggest Feed Production Challenges

3.1 Challenge 1: Low efficiency → Full-automatic lines double your output

A fully automatic production line solves efficiency problems with:

- Integrated process: crushing, mixing, pelleting, cooling, packaging

- High capacity: 2–10 tons/hour depending on model

- Easy operation: touchscreen system, 1–2 days training

Case: A farm in Abuja upgraded to a 5-ton/hour line and increased daily output from 8 tons to 40 tons, supplying three nearby farms.

3.2 Challenge 2: Unstable feed quality → Smart dosing keeps nutrition consistent

Professional machinery provides:

- Accurate weighing: ±0.5% error vs. 5% by manual mixing

- Customizable formulas: 10+ Nigerian raw-material presets

- Real-time NIR testing: monitors protein, moisture, alerts for abnormal data

A feed mill using this system improved qualified feed rate from 75% to 99%, reduced broiler growth cycle by 3 days, and increased repeat orders by 20%.

3.3 Challenge 3: Raw material waste & high cost → Better utilization saves 15%

Cost reduction comes from:

- Pre-cleaning: removes 10–15% impurities

- Dust-free crushing: increases utilization from 85% → 95%

- Energy-saving motors: 20% lower power usage

- Reduced labor: only 2–3 operators needed instead of 5–8

A small farm cut their cost from ₦120,000/ton to ₦102,000/ton — saving over ₦500,000 annually.

3.4 Challenge 4: NAFDAC compliance → Built-in hygiene & testing makes approval easier

Compliance features include:

- 304 stainless steel contact surfaces

- On-line testing for moisture + heavy metals

- Auto-log production data for 2+ years

A Kano feed mill passed NAFDAC approval in just one month and entered Shoprite stores, boosting sales by 35%.

4. How to Choose the Right Broiler Feed Machine for Your Production Scale

4.1 Small farms (1–5 tons/day): Compact mini pellet lines

- Small footprint: 2m × 1.5m × 1.8m

- Affordable: ₦500k–800k

- One-machine solution: crushing + mixing + pelleting

Perfect for farms with 500–2,000 birds.

4.2 Medium cooperatives (5–20 tons/day): Semi-automatic lines

- Includes hammer mill, double-shaft mixer, ring-die pellet mill, cooler

- Supports 2–3 feed types

- Cost: ₦2M–₦4M; payback in 8–12 months

Ideal for cooperatives or farms with 2,000–10,000 birds.

4.3 Large farms & feed mills (20+ tons/day): Fully automated smart lines

- Remote monitoring, automatic adjustments

- Siemens motors + Mitsubishi PLC

- Full NAFDAC compliance package

Perfect for industrial feed production or regional distribution.

5. Real Nigerian Customer Cases: How the Right Equipment Changed Their Business

5.1 Case 1: Lagos small farm — From “not enough feed” to “selling surplus”

- Farm size: 1,500 birds

- Problem: manual production only 2 tons/day

- Solution: 1-ton/hour mini pellet line

- Result:

- Output jumped to 8 tons/day

- Selling 6 tons/day to neighbors

- Cost dropped ₦18,000/ton

- Survival rate improved 82% → 90%

5.2 Case 2: Kano feed mill — From “non-compliant” to supermarket shelves

- Previous output: 300 tons/month

- Problem: not NAFDAC-approved

- Solution: 5-ton/hour semi-automatic line

- Result:

- Output doubled to 600 tons/month

- Passed NAFDAC in 30 days

- Sales rose from ₦18M → ₦45M/month

Case takeaway:

Choosing the right equipment consistently delivers:

- Lower cost (10–15%)

- Better quality

- Higher efficiency + less labor

6. Why Partner With Us: Designed for Nigeria, Built for Long-Term Success

6.1 Local service network — 24/7 support

Service centers in Lagos, Kano, Abuja offering:

- Installation & commissioning (within 3–5 days)

- On-site training

- 24/7 hotline + 24–48h repair response

6.2 Customized for Nigerian raw materials & factories

We provide:

- Parameter adjustments for high-moisture maize

- Layout design based on your factory size

- Expandable line designs for future growth

6.3 Long-term support

- 1-year warranty for key parts

- Spare parts warehouse in Lagos

- Lifetime maintenance (only pay for parts)

6.4 Financing support

In partnership with UBA and Standard Chartered Nigeria:

- 30% minimum down payment

- 6–12 month installments

- Interest rate as low as 8%

- Fast approval within 7 working days

7. Conclusion: Nigeria’s Broiler Feed Market Is Full of Opportunity — Start With the Right Equipment

Nigeria’s 3-million-ton feed gap makes now the perfect time to invest in feed production.

But traditional methods and NAFDAC requirements mean your equipment choice determines your success.

The right machinery helps you:

- Lower cost

- Improve quality

- Increase efficiency

- Pass NAFDAC smoothly

Whether you run a small farm or a large commercial feed mill, we can provide a tailored solution for you — plus a free copy of our “NAFDAC Compliance Guide for Nigerian Feed Producers.”

Ready to grow your business in Nigeria?

Send me a message and let’s build the right feed production system for you!

Back to List

-

.jpg) 2025-12-04Nigeria’s Broiler Feed Production: Opportunities, Challenges & Smart Equipment Solutions

2025-12-04Nigeria’s Broiler Feed Production: Opportunities, Challenges & Smart Equipment Solutions -

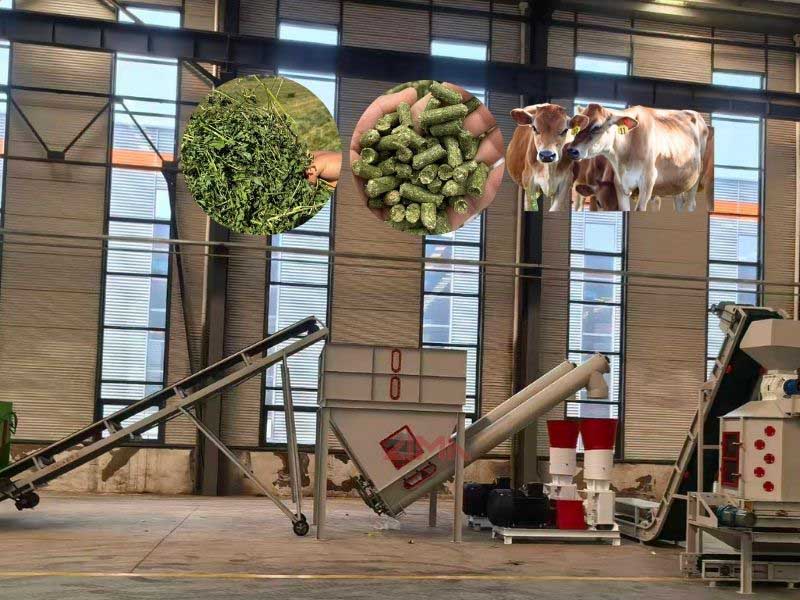

2025-10-211~2ton/h Cattle Feed Production Line 50% Grass formula Poultry Feed Mill Plant

2025-10-211~2ton/h Cattle Feed Production Line 50% Grass formula Poultry Feed Mill Plant -

2022-12-09Trace Elements in Floating Fish Feed and Their Importance

2022-12-09Trace Elements in Floating Fish Feed and Their Importance -

2022-10-18Problems And Solution Of Floating Fish Feed Making Process?

2022-10-18Problems And Solution Of Floating Fish Feed Making Process? -

2022-09-30At what stage does catfish start growing faster?

2022-09-30At what stage does catfish start growing faster?